Description

Fadini Coral F/1080L Bollard

DESIGN AND MANUFACTURING

Recommended to control access to residential areas and also for commercial and industrial applications.

OIL-HYDRAULIC

Hydraulic block for parking in high position (diverse series) and operation to emerge with the lock in place. Electric valve (optional) for the automatic disc in the event of a lack of electrical power. Collaudato for intensive use at low and high temperatures

EASY ACCESS TO THE OIL-HYDRAULIC COMPONENTS

The handy housing position of the motor pump and oil-hydraulic actuator inside the bollard allows for easy maintenance and reduces service and installation times. In this way the components are also more protected, rust and other factors of deterioration are prevented.

SIMPLE AND QUICK TO INSTALL

Reduced weight of the pit so that no particular excavation or brick works are needed. Cataphoresis treated and polyester powder coated scratch-proof steel cylinder, head with rubber edge. Hall effect limit switch sensors, LED lights (optional).

VERSATILE

A vast range of command and safety accessories allow for reliable and precise control of the installations. The electronic control unit can be set so that it can manage several bollards at a time.

FREE UK Mainland Delivery

To see our Full range of Fadini Bollards, click here

For more information from the manufacturer, click here

Are you unsure which type of gate automation is best for your situation or need technical assistance? We have over 30 years of experience in the Gate Automation industry, so feel free to call us on 01223 839991 or email us at [email protected] for free expert advice.

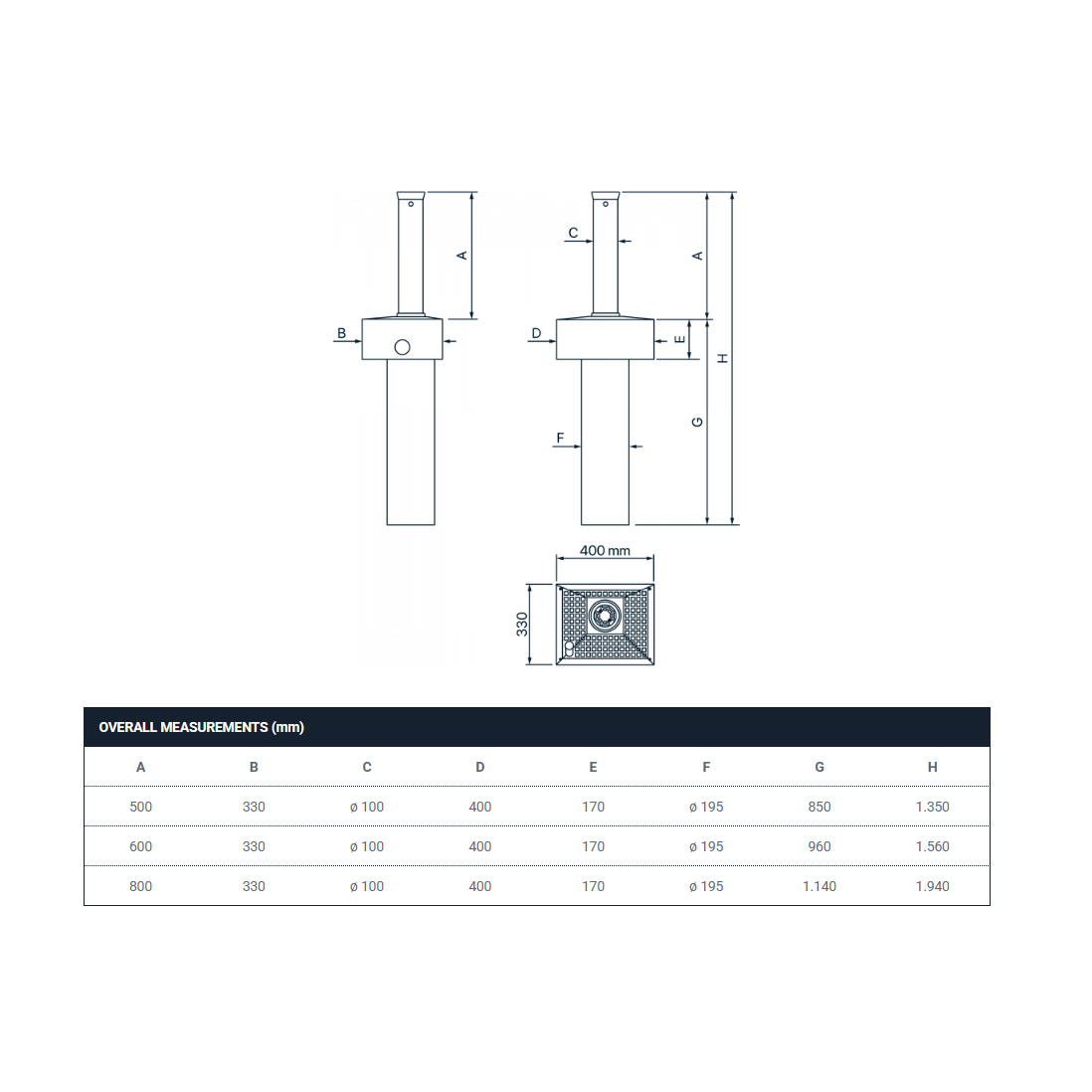

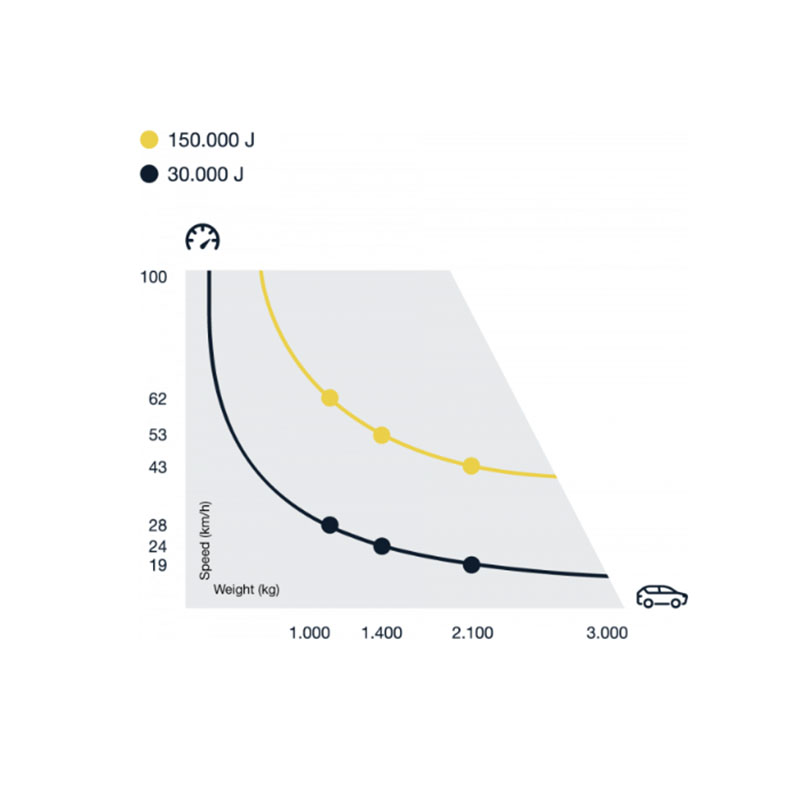

Fully retractable, heavy duty, automatic bollard consisting of an oil-hydraulic motor-pump unit incorporated inside the main structure and an oil-hydraulic actuator inside the moving cylinder. Suitable to meet residential, commercial and industrial requirements and urban applications. IP 67. Height from ground level can be 500, 600 or 800 mm. Scratch-proof S235JRH steel moving cylinder, thickness 5 mm and ø 100 mm, cataphoresis treated and polyester powder coated. Cylinder head made of aluminium with rubber edge, cataphoresis treated aluminium cover plate. Head and cover plate are slip-proof and tread resistant. Moving cylinder fitted with an approved, retro-reflecting, high intensity, micro-prismatic, high intensity adhesive film (h 80 mm), available with No. 4 amber-colour signalling LED lights flashing and radially fitted, 10 m electric cable. Hot-dip galvanized steel pit. Cover plate allowing access to the hydraulic release device for the manual lowering of the bollard by a special spanner in an emergency. Impact resistance 30.000 J, breakout resistance 150.000 J, static load max 1.600 kg (bollard in raised position), max 20.000 kg (in lowered position). Working temperature -40 ÷ +80 °C. Supply voltage 230 Vac ± 10%, 50 Hz. Absorbed power 330 W. Rising time ~ 4,7 s [h 500 mm from ground level], ~ 5,6 s [h 600 mm from ground level] ~ 7,5 s [h 800 mm from ground level]. Intensive use, 2.000 cycles/a day.

Free UK mainland delivery on orders over £100

(1 - 2 working days)

Free UK mainland delivery on orders over £100

(1 - 2 working days)

Instruction Manuals and Downloads

Instruction Manuals and Downloads Ask a question

Ask a question

Fadini Coral F/1084 Instruction Manual

Fadini Coral F/1084 Instruction Manual

Reviews

There are no reviews yet.